Atomic Layer Deposition

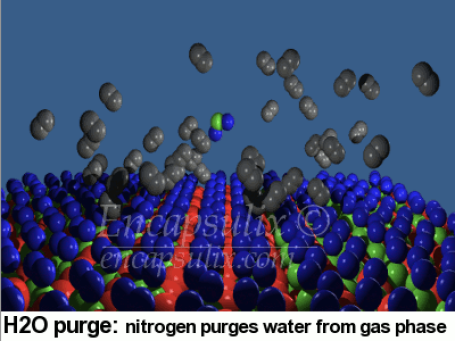

ALD (Atomic Layer Deposition) is the sequential introduction of propagating waves of metal and oxygen precursors yielding Angstrom level process thickness control. Encapsulix’s innovation has decreased the cycle time and increased the substrate size capability of the ALD process dramatically.

Encapsulix Innovation: An assembly of modular precursor dosers and gas injectors that behave as a monolithic “unit” -Assemble application-specific systems based on common technology bricks

-Factor of 5-100 throughput increase through massive parallel deployment

-Commonality in hardware, Process between R&D, Prototype, Manufacturing Economic large area atomic scale barrier film deposition.

In addition, Encapsulix has developed an innovative plasma option, that can be used for in-situ preclean, plasma enhanced ALD and plasma densification of the coatings.

Nous avons besoin de votre consentement pour charger les traductions

Nous utilisons un service tiers pour traduire le contenu du site web qui peut collecter des données sur votre activité. Veuillez consulter les détails dans la politique de confidentialité et accepter le service pour voir les traductions.